Škoda opens state-of-the-art pre-production facility dedicated to development, test and simulation as well as assembly

Škoda Auto has taken prototyping to the next level with a dedicated facility for new models to test, analyse and prepare the vehicles for volume production.

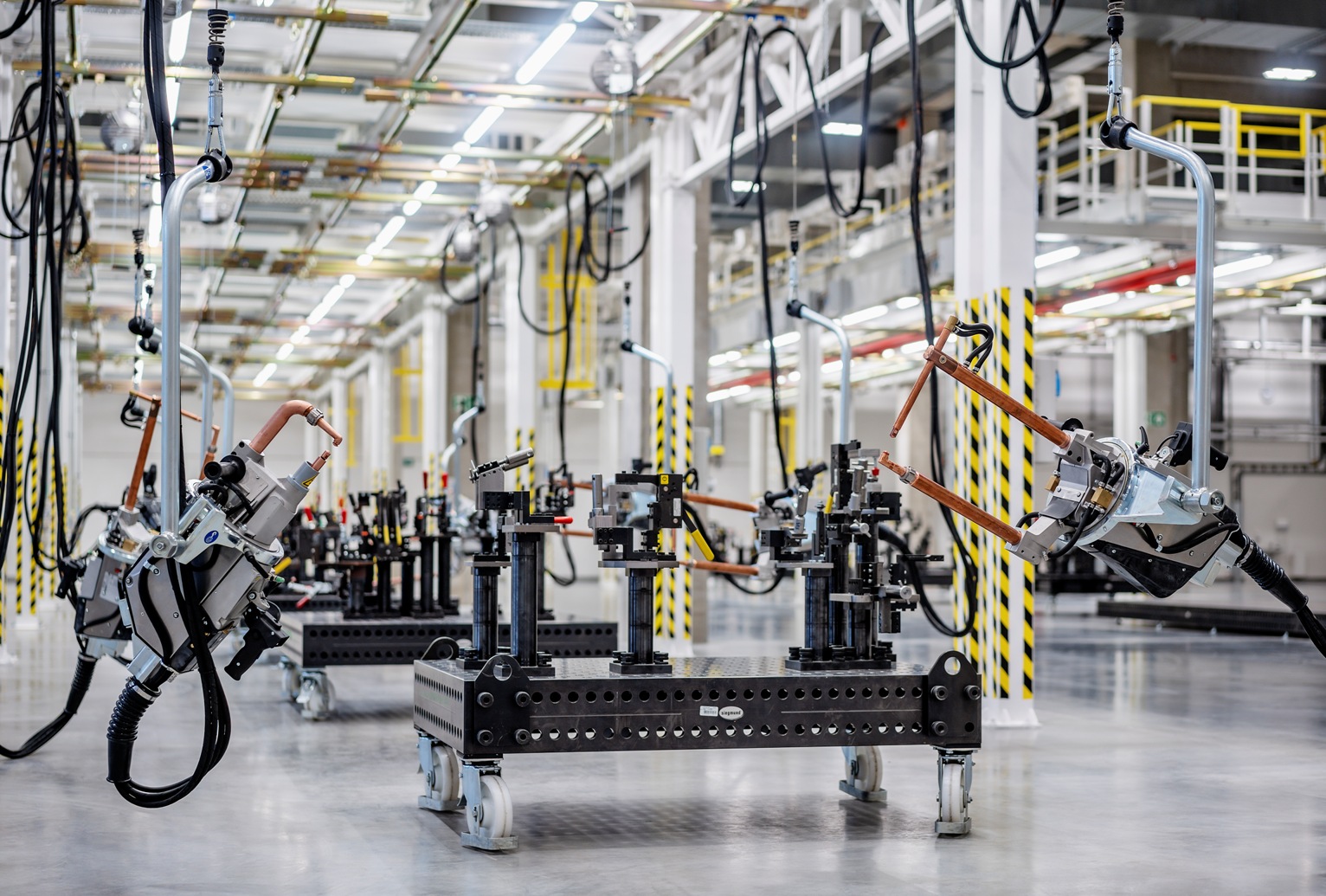

The new Central Pilot Hall has been put into operation at its headquarters and in the development phase of new models, comprehensive analyses will be carried out there and pre-production cars manufactured. They will be subjected to extensive testing by the Technical Development and Quality Assurance departments prior to the launch of serial production. The facility houses, among other things, a body shop and an assembly shop as well as a measuring centre and a virtual reality studio. The central pilot hall is also prepared for the era of electro-mobility, with charging points and relevant assembly areas including options for testing electrified vehicles.

Škoda Auto believes the 20.4 million euros spent on the project is an investment in the future and, following its new centre to build test vehicles and prototypes, is opening yet another state-of-the-art facility to work on pre-production models.

According to Dr Michael Oeljeklaus, Škoda Auto’s Board Member for Production and Logistics, the Pilot Hall will act as an interface between the company’s Production and Logistics, Technical Development and Quality Assurance departments in the run-up to start of production. The necessary preparations will be made there to ensure a smooth commencement of serial production of new models.

“Fitted with ultra-modern equipment, the new Central Pilot Hall offers the ideal prerequisites for carrying out complex analyses, for example, to perform the necessary tests and inspections, or to optimise machines and tools before we use them in series production,” he says.

Experimental factory

The new central pilot hall provides the Škoda Auto engineers with their own little factory. In addition to robot stations where the car bodies are joined, the new facility also houses areas for assembly and final inspection. Virtual reality devices and 3D printers are some of the tools available. The equipment and processes are designed in such a way that both vehicles with a combustion engine and partially or fully electric cars can be subjected to all the necessary tests and analyses. As soon as a model meets the stringent quality requirements, it leaves the Pilot Hall – the vehicle and processes are then considered ready for volume production.

The two-storey building on the factory site is 22 m high and covers an area of 12,142 m² – equivalent to more than one-and-a-half football pitches. It offers excellent working conditions for the permanently based staff as well as for employees from other departments and visitors. In addition to rooms for meetings and training courses, there are also charging stations for all-electric vehicles. A light tunnel creates the best conditions to present the pre-production vehicles.

In order to be able to use the latest technology for the assembly of pre-production cars in the future, the facility is designed to be retrofitted with such equipment as flexible robot cabins if required.

Originally, the building was used for the electrogalvanization of Škoda 100 bumpers, and later the car maker used the complex as a warehouse. Now that the conversion, which began in September 2019, has been completed on schedule, the space and much of the building can once again be used more effectively. The new central pilot hall also meets the highest standards in terms of energy efficiency.