A filter has been developed and has passed endurance testing for removing microplastic debris from tyre wear on city streets

The Audi Environmental Foundation has developed filters for urban runoff in conjunction with the Technical University of Berlin. They prevent tyre wear particles and other environmentally harmful substances from being washed into sewers and bodies of water. Initial field and lab tests have now demonstrated the efficiency of the system.

As much as 110,000 tonnes of tyre and road wear particles ends up on the streets in the form of microplastics every year in Germany alone. From there, it is blown into the environment by the wind, or is washed by the rain as urban runoff through the sewers into the soil and rivers. “Our goal is to take preventative actions wherever possible so that fewer microplastics get into the environment,” says Rüdiger Recknagel, Director of the Audi Environmental Foundation.

Together with the Technical University of Berlin, Audi is therefore developing an innovative new filter concept for urban runoff. These filters can be combined individually depending on the road and traffic situation. They trap the respective dirt particles as close as possible to the location where they are generated – before rainwater can rinse them into the sewers.

Laboratory and road tests

Tests in a laboratory at TU Berlin have shown that without clogging up, the filters managed to permanently trap “genuine” street cleaning waste, cigarette filters, microplastics in the form of plastic granulates up to three millimetres in size and other debris. “The system does this not just when it’s drizzling, but also when it’s raining hard,” says Daniel Venghaus, research associate in the Department of Urban Water Management at TU Berlin.

As part of the testing, a filter was also deployed on a busy road in Berlin, where it successfully mastered its first stress test during a series of storms in mid-February. It is due to remain in service at its present location until the end of the year. The researchers want to take samples both of the intake and of the water draining away to determine its effectiveness in real-life operating conditions throughout the seasons. Furthermore, initial discussions are already underway with the ADAC Driving Safety Centre in Berlin-Brandenburg to install filters on its routes to gain a better understanding of the filtering of wear particles in different driving situations.

Nine modules for different uses

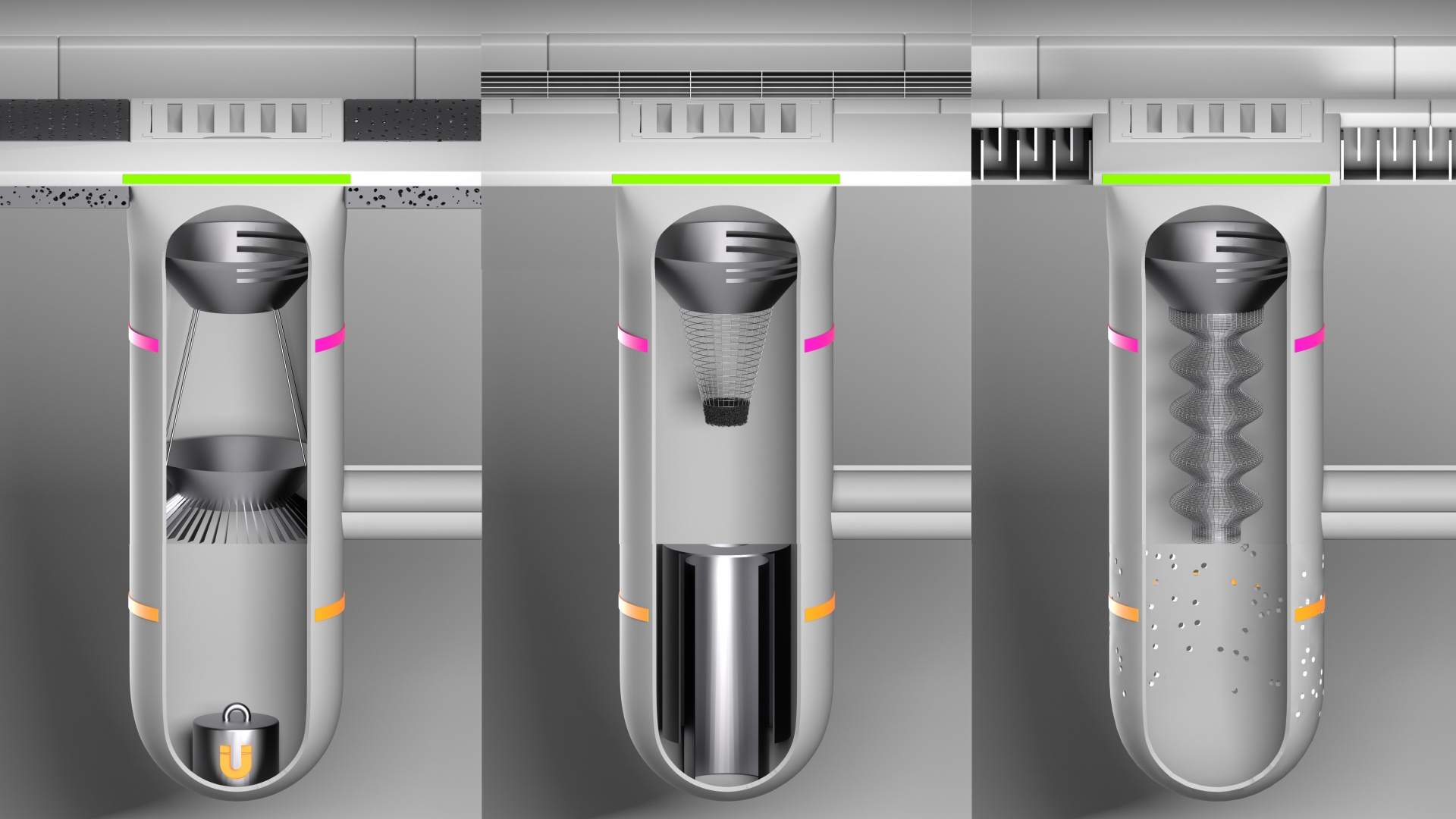

The sediment filters are divided into three zones – street, sewer, and drain – and consist of nine modules. Up to three modules can be combined to achieve the best result depending on the location. In the uppermost area (road), this might be a special runoff channel. Below this, in the sewer itself, larger solids are filtered out, for example, with the aid of an optimised leaf basket or what is known as a filter skirt. The lowest area (drain) is about fine filtration, for which a magnet module can be used.

The goal of the tests and of further development work is for the filter to be in operation for up to a year without having to be maintained or cleaned. This is where intelligent connectivity comes into play. A lot of different information converges here, such as the street cleaning schedule, the traffic volume on the street, rush hour times, and the weather forecast. This even includes whether there are a lot of trees along the roadside or whether it is a popular area for dog walking. Based on these factors, it is possible to predict the contamination level of each individual filter and determine when the best time to empty it is.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020