Test instrument provides means for automated compliance testing of PCie 5.0 and 6.0 connectors and cables

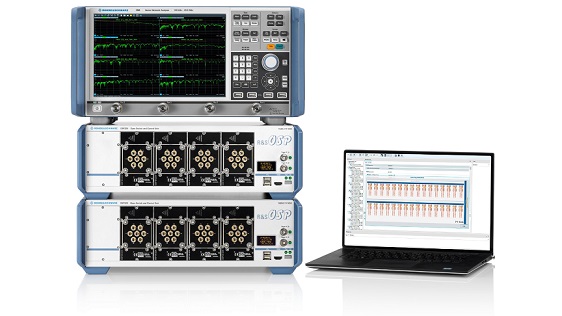

Rohde & Schwarz has taken an approach to efficiently tackle compliance verification challenges for PCIe 5.0 and 6.0 cables and connectors by automating the process with a new R&S ZNrun vector network analyser automation suite option. R&S ZNrun-K440 is designed for automatic compliance testing of PCIe 5.0 and 6.0 internal and external cables and connectors in line with PCI-SIG specifications, saving users a lot of time. The test setup is based on the R&S ZNB26 or R&S ZNB43 vector network analyser with four test ports in combination with multiple open switch and control platforms – depending on the number of the DUT lanes for verification – to provide multiple four-port measurements, all without reconnecting to the DUT and repeatedly terminating the other lanes. A PCIe x8 cable, for example, has 16 lanes and requires 64 test ports, provided by three R&S OSP320 platforms, while a PCIe x4 cable only needs 32 test ports from two R&S OSP320 platforms.

The R&S ZNrun-K440 fully automates all measurements in line with the PCIe specification. Postprocessing of defined PCIe metrices is also covered. A powerful test configurator lets test items be selected and deselected by lane for greater flexibility in meeting customer needs and preferences in R&D and verification testing. A test report with a pass/fail verdict is generated at the end of the automated measurement. The automation features a new calibration procedure, which significantly reduces the number of calibration steps and connections. It also includes a method for de-embedding of the test fixture as required in the PCIe test specifications.

Increasingly complex testing

Each iteration of the PCIe evolution has doubled the transfer rate to meet ever increasing demand for speed. Data centres across the world are starting to use the latest versions of PCIe 5.0 and 6.0 cables to connect large amounts of high-speed data storage. Cable manufacturers are also ramping up production to deliver the first PCIe 5.0 and 6.0 cables to customers. R&D verification, compliance testing and manufacturing all require thorough testing to guarantee compliance with PCIe requirements and the proper functioning of the overall system.

Each PCIe link has 1, 2, 4, 8 or 16 lane pairs, with each lane pair consisting of one differential TX and one differential RX lane. With 8 lane pairs in a x8 configuration, a PCIe 6.0 cable can have transfer rates of up to 64 GB/s. Manually verifying compliance of high-speed interconnect is labour intensive and error prone. A total of 256 four-port measurements are needed for all Thru connections and all near-end and far-end crosstalk paths inside the cable. With traditional four-port vector network analysers, a VNA must be reconnected for each four-port measurement and unmeasured lanes must be properly terminated. The new automated approach from Rohde & Schwarz drastically simplifies this process.

Since certain limit mask excursions are not critical for overall PCIe 5.0/6.0 system behaviour, pass/fail verdicts are based on metrices such as integrated return loss (iRL) and component contribution to integrated crosstalk noise (ccICN). They are defined in the PCI-SIG specification and need to be calculated from the S-parameter results and require significant postprocessing. Calibrating test fixture characterisation and de-embedding brings additional challenges. R&S ZNrun-K440 software for automatic compliance testing covers them all.

Because of their importance to PCIe systems, PCI-SIG is in the process of defining standardised cables for internal (inside a chassis) and external (chassis-to-chassis) applications, including the corresponding electrical requirements for mated cable assemblies and mated cable connectors at both 32 GT/s and 64 GT/s. R&S ZN-run-K440 will also cover these PCIe tests, once they are standardized.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020