An inline 3D profile measurement system inspects geometry of long strip products in hot and cold rolling mills

Micro-Epsilon has introduced a range of inline 3D profile measurement systems for the geometrical inspection of long products in metal processing. Depending on the application and profile shape, the measurement systems can be equipped with either ThruBeam sensors, red laser profile scanners or blue laser profile scanners to provide the optimal solution for the application.

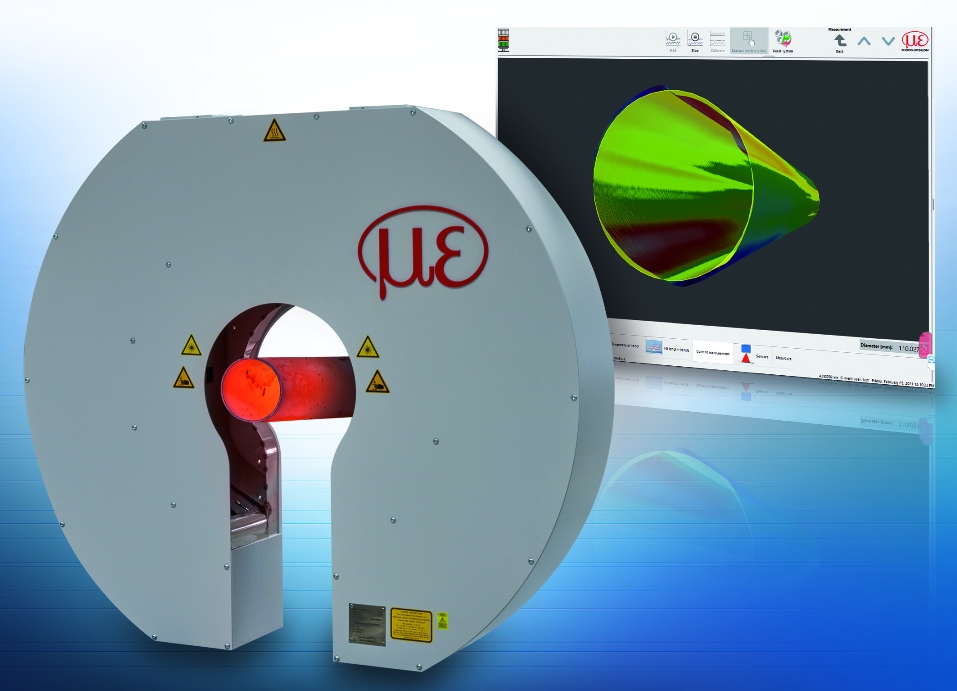

Long strip products such as profiles, billets and tubes, which are produced by rolling, drawing or forging, often have complex cross-sectional geometries. The new dimensionCONTROL Metal Profile Gauge (MPG) measuring systems have a compact, horseshoe-shaped design that allows them to be easily integrated directly into metal processing lines. Fully automatic calibration compensates for any potential temperature-related long term drift of the mechanical structure, resulting in a reliable inline measurement system for process control of hot and cold rolled products.

Inside the frame are six laser profile triangulation sensors and a fully automated calibration system. The lasers project straight lines onto the surface to be measured. These lines from each sensor are combined to provide a complete profile around the circumference of the target. The basic calibration of the sensor serves as a reference to convert the deviation into real/actual measured values. Pneumatic protection of sensor optics and optional water cooling is available for harsh, hot environments.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020