GE has been testing high power, high voltage hybrid electric components in altitude conditions

The company has completed the world’s first test of a megawatt (MW)-class and multi-kilovolt (kV) hybrid electric propulsion system in altitude conditions that simulate single-aisle commercial flight.

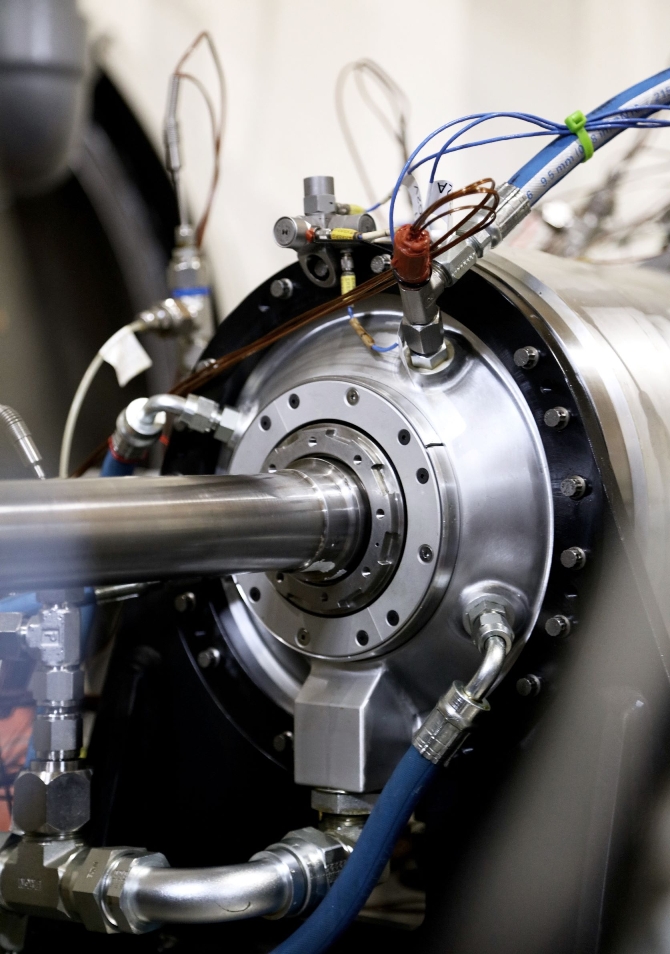

The test included electric motor/generators, power converters, power transmission and power control systems and successfully demonstrated performance and operation of the components in a replicated flight environment. This helps validate the architecture of the hybrid electric propulsion systems GE is developing. It’s also an important, necessary step in GE’s technology programs with NASA to develop a hybrid electric propulsion system for flight tests later this decade and for entry into service in the mid-2030s.

The altitude integration test of the system began in June 2021 and was completed earlier this year at NASA’s Electric Aircraft Testbed (NEAT) facility in Sandusky, Ohio. To represent the right and left engine side of an aircraft, two sets of a hybrid electric system were operated in conditions up to 45,000 feet, simulating the electrical loads required to help optimise the engines and propel and power an aircraft.

The NEAT facility where testing took place is a NASA reconfigurable testbed used to design, develop, assemble and test electric aircraft power systems.

The facility is the only testing location capable of simultaneously providing both high-electric power and high-altitude conditions in an area large enough to fit an entire electric powertrain.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020