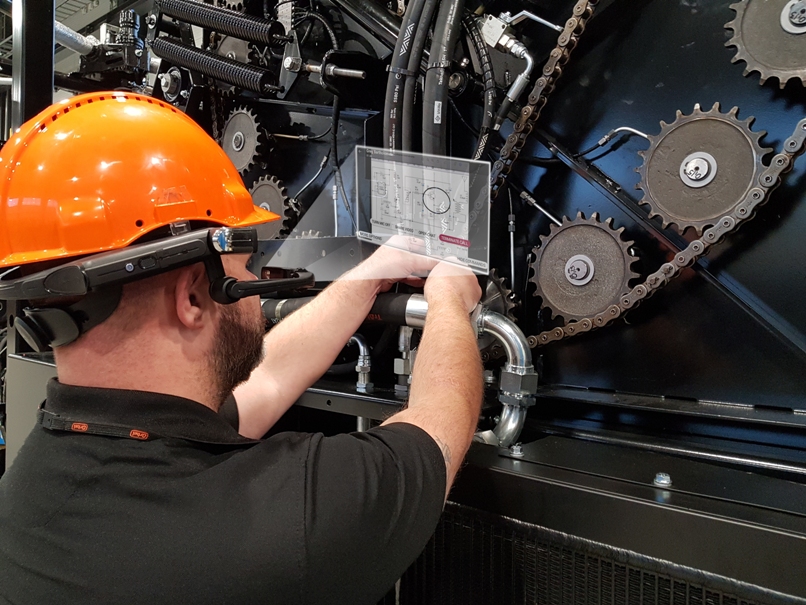

Installation and maintenance workers operating with heavy machinery gain assistance with over-the-air assisted reality

RealWear, a provider of assisted reality systems for use by frontline industrial workers, is now supplying wearable devices to Orkel, a Norwegian manufacturer of compactors and other machinery for agriculture, industry and waste management. Orkel aims to provide real-time customer and product support, eliminating waiting times for in-person visits and avoiding costly downtime delays for farmers.

The company’s initial purchase of 40 units will be used for remote after-sales maintenance, remote servicing and remote commissioning of all its heavy agricultural machinery products. This technology will provide technical expertise guidance during commissioning, if necessary, where Orkel staff are unable to travel to a site. Orkel’s research and development team tested a variety of smart glasses before standardising on RealWear’s HMT-1 head-mounted displays. According to Orkel, RealWear’s rugged form factor, safety features, noise cancellation and long battery life were deciding factors.

The innovative system allows Orkel to connect its customers to its service technicians without the need for unnecessary travel. As part of its after-sales support, each customer in need of commissioning or a technical service receives a kit consisting of the HMT-1, a branded Orkel hardhat, and mounting clips. The customer simply puts on the device, contacts the Orkel technician using voice commands and, after connecting, the technician can immediately see exactly what the customer sees through the head-mounted camera and easy to use software – VSight. The technician then solves the issue.

The solution solved a number of difficulties for Orkel. For instance, typically its service technicians were required to make an in-person customer trip, which involves travel time and environmental costs. A delay in fixing the equipment also has the potential to impact the customers’ businesses.

“Our customers really appreciate the value of the system because we are able to provide a much faster level of support when an issue arises. All too often, our service technicians would travel for what turned out to be a quick fix. Now, with RealWear, many hours of time and CO2 emissions are saved, and most importantly customers’ machines are operational again quickly, which is imperative during the harvest season,” commented Svein Erik Syrstad, Technician, Orkel.

As the farming and agriculture sectors are heavily dependent on the harvest season, Orkel’s customer base requires maximum uptime from their Orkel machinery, especially during the busy season.

On the device, Orkel is using RealWear partner VSight Remote, a remote service and collaboration platform powered by AR that helps manufacturing companies conduct maintenance operations remotely with Augmented Reality. It is also using a voice-optimised version of Microsoft Teams with the RealWear devices for internal communications with staff. The Orkel machine’s telemetry system ensures that details about every aspect of the machine’s operation is sent securely to the cloud, enabling Orkel’s service technicians to read the data and guide their customers to the next step in the procedure. This information enables Orkel to target the specific error more efficiently, and then guide the operator remotely to resolution.

“For me, this is great technology because as a research & development engineer, I can watch the work being done,” said Magnus Nordås Lervik, Project Engineer, Orkel. “I’m quickly learning better ways to design future machinery as I’ve seen first-hand the common issues that arise, and how they are fixed.”

Jon Arnold, Vice President of EMEA, RealWear says Orkel and its customers are achieving a number of benefits since deploying RealWear’s technology. “When looking at the agricultural industry as a whole, machine downtime impacts productivity and efficiency, especially in shorter and shorter harvest seasons. Remote assistance with RealWear is becoming a gamechanger for the farming and agriculture industry when every second matters,” he concludes.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020