Aeva’s LiDAR-on-Chip Sensing Technology will be used in Nikon’s industrial metrology and quality control products for high volume automotive manufacturing, aerospace and energy industries

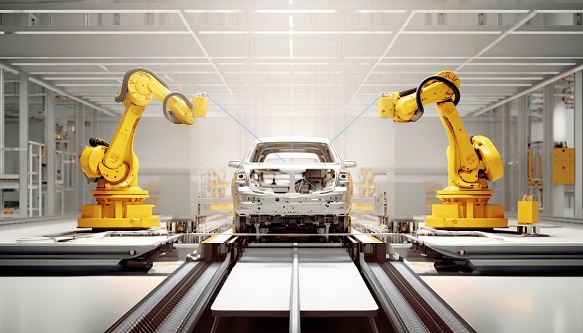

Nikon’s technology powers high-precision, automated quality control in high-volume manufacturing environments by enabling non-contact measurements from long distances with very high speed and precision. In the automotive industry, for example crucial measurements taken during Body-in-White and Gap and Flush inspections ensure the accuracy and quality of vehicle components during production assembly.

The perception technology in the LiDAR product opens up new possibilities for Nikon’s metrology systems thanks to its high accuracy and faster measurement capability, according to Tadashi Nakayama, CEO at Nikon Metrology.

Aeva is equally pleased to be moving into manufacturing and metrology as it validates that the technology goes well beyond its existing application in automated driving with a perception platform powering the next wave of manufacturing automation.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020