A location independent and rapid deployment laboratory for climatic testing of EV batteries can be installed at supplier premises

Two companies involved in vehicle environmental testing technology have collaborated to obtain improvements in battery test systems for electric vehicles. Software and test hardware specialist, Keysight Technologies, joined forces on the project with Proventia a Finnish technology company that provides test chambers for use in the engine, machine and vehicle manufacturing industries.

With an imperative for automotive manufacturers, their supply chains and test service providers to increase the driving range of EV, whilst also increasing their performance and safety, the ability to achieve reduced time to market and keep costs within budget are also high on the agenda.

When developing and testing high-voltage EV batteries, time becomes critical in a competitive market so the collaboration between Keysight and Proventia delivers a location-independent and safe test lab with rapid implementation time.

The rapidly deployable and location agnostic test facility being offered by the joint project has a number of key features, including Keysight’s Scienlab battery test systems, including the SL1700A series Scienlab Battery tester, a pack level system to test high-voltage batteries of up to 1500V. It addresses safety concerns with features including redundant measurement and uses new high-voltage silicon carbide (SiC) technology allowing an energy recovery capability of 96%.

The test system also incorporates Keysight’s Scienlab energy storage discovery software, which controls and monitors test systems and lab components from the device under test (DUT), including the battery management system and climatic chambers. PathWave software manages lab operations for battery testing helping to manage the entire lab and optimise its workflow, data acquisition and handling.

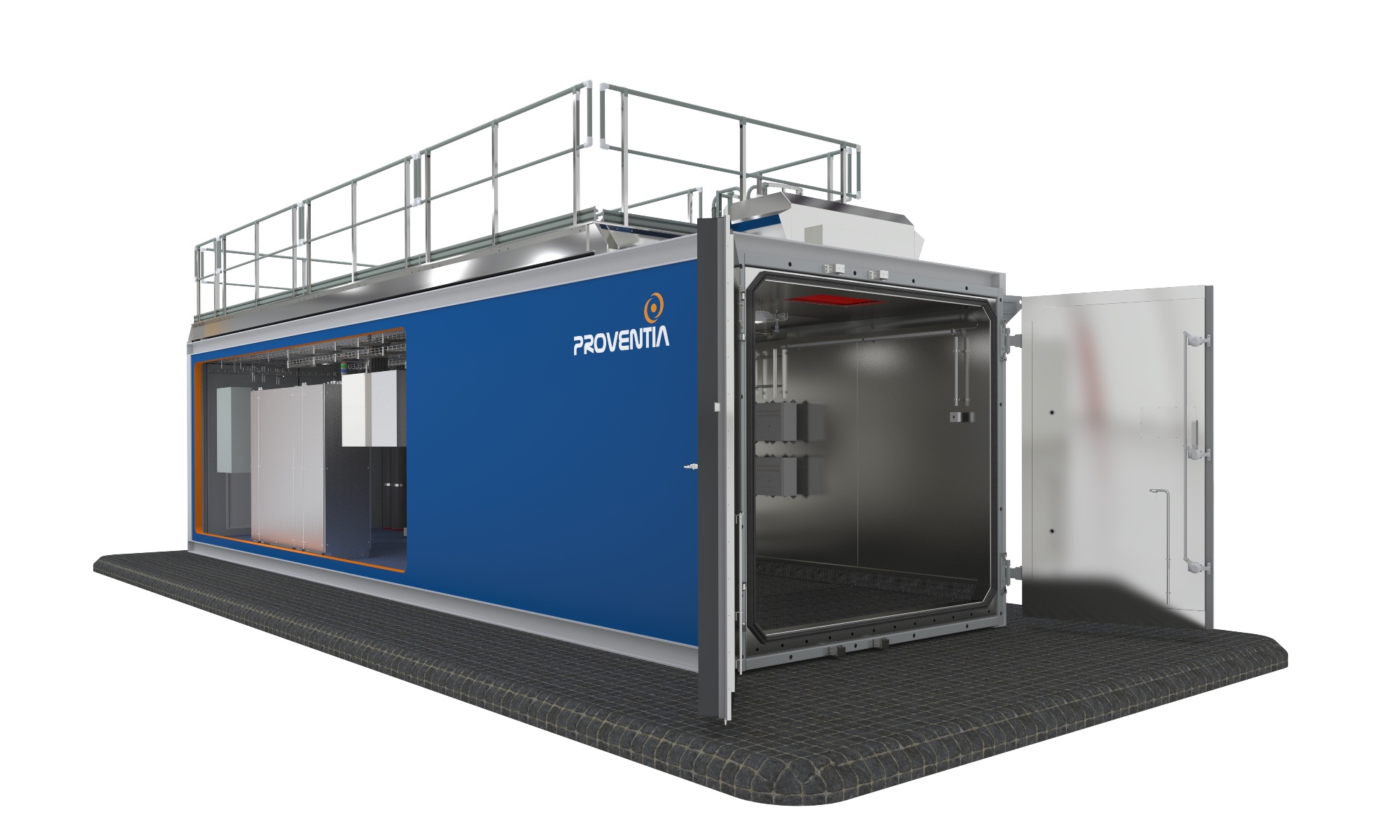

Proventia’s standardised, modular test chambers reduce investment time and costs with scalability that enables users to choose from a number of configurable test chambers of different sizes for rapid deployment. The Proventia test laboratories include climatic chamber integration and control, liquid conditioning systems, air conditioning, a control room and DUT preparation space. To prevent hazardous situations and ensure the health of employees when testing batteries, safety features include gas and fire detection, a facility alarm system and access control.

According to Proventia, extensive testing and validation of the EVs battery packs and modules ensures they perform as expected in the environment in which they will be used. The company’s climatic EV battery testing chambers are designed for both module and complete battery pack requirements.

They enable real-world performance simulation, charging and discharging performance testing as well as checking for the effects of temperature and humidity. The large climatic chamber can be located inside or outside a building, and allows full vehicle packs to be cycled between -40 and 90 degrees C, and 10 to 95% relative humidity. The chamber has a 1MW cycler capability with the ability for parallel connections between cyclers.

According to Jari Lotvonen, president and CEO of Proventia, Combining the experience and knowledge of Proventia with Keysight has enabled the companies to quickly deliver an optimised battery test lab that meets the needs of the industry.

The joint efforts of the two companies have enabled them to offer users a modular, safe and fast-to-build test lab infrastructure equipped with sophisticated battery test solutions, according to Thomas Goetzl, vice president and general manager for Keysight’s Automotive & Energy Solutions business unit.

“This enables customers to accelerate time-to-market of their battery products without compromising performance, quality and test coverage,” he concludes.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020