GTM platform provides one measurement, three axes, six components from one multicomponent transducer

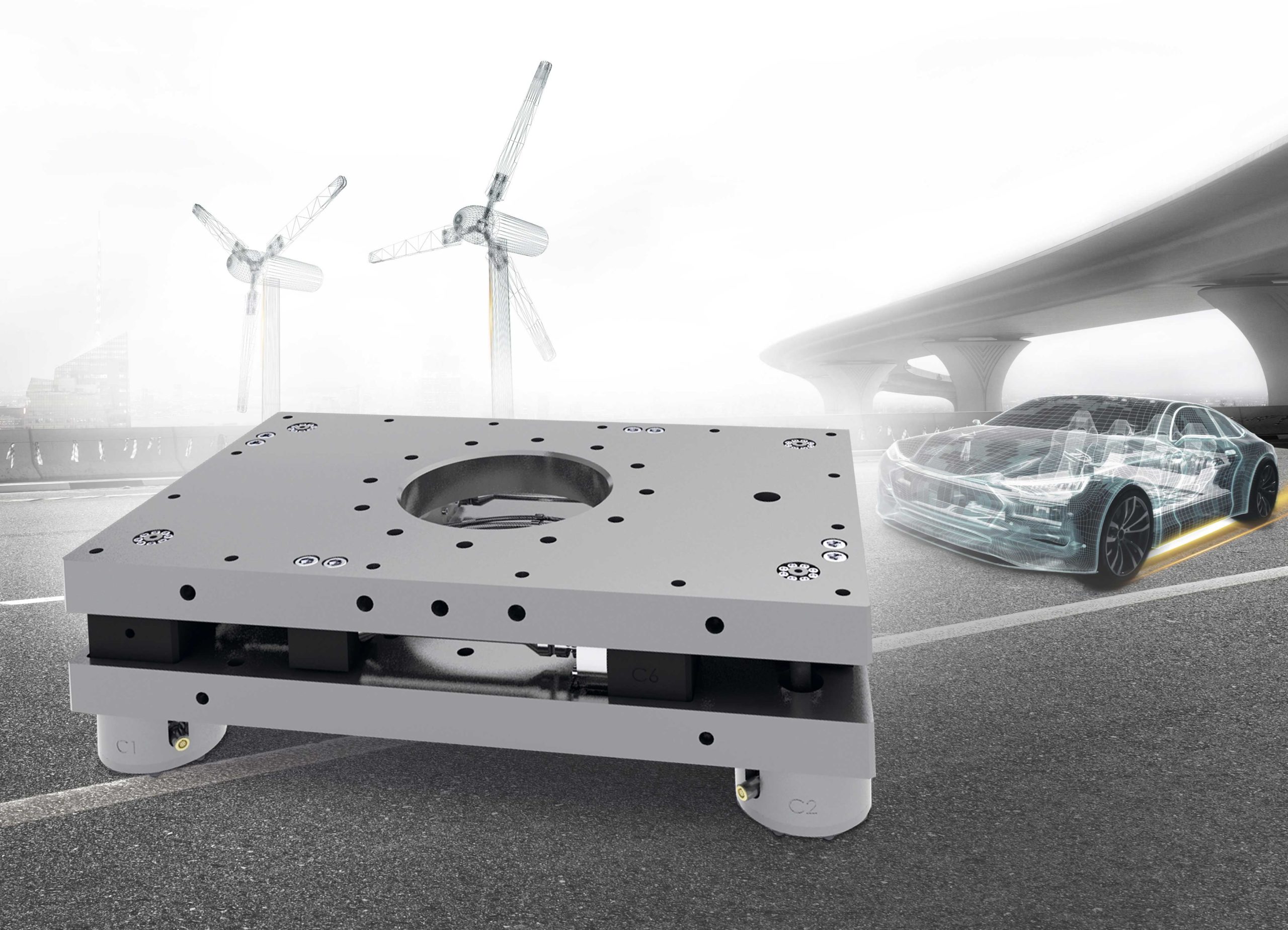

With the MPF-series measuring platform, GTM is offering custom-tailored, high-precision multicomponent measuring platforms for use in high-end multi-axis test benches, for instance for heavy-duty functional, component and structural testing.

When it comes to force and torque measurement technology, there are times when even high-precision standard transducers just won’t be enough. If, for example, you need to simultaneously measure forces and torques along multiple vector axes for automotive, medical or robotics applications, you’ll often be better served using multi-component transducers.

The MPF-series equipment is designed for use along the three axes (x, y, z) and features several separate high-precision force transducers. These are precisely aligned and mechanically decoupled from one another. This ensures multi-component measuring at maximum accuracy.

For each platform, GTM works with users to tailor it specifically to its actual use case and then manufactures the equipment. It is fitted with the exact number of force transducers required, in most cases six, seven or eight separate force transducers.

Typically, such platforms are used where sensitivity and accuracy requirements differ along the various axes. This would be the case in wind tunnels or rolling resistance test benches, for example.