Automotive test house uses sensor signal analysis instrument in harsh dynamometer and NVH testing environments

Test houses that offer drivetrain testing services to the automotive industry need to be have the flexibility to be able to adapt to a wide range of different requirements and levels of system testing. With potential customers ranging from suppliers of specialist components for the powertrain or transmission, right up to the world’s main car manufacturers, the test houses need adaptable test systems that can be quickly broken down and rebuilt to meet the needs of each customer.

One such test specialist is ATESTEO based in the German town of Kassel, from where the company coordinates the provision of its services to the industry and which recently had additional requirements for a test system to equip its automotive test stands.

ATESTEO is an independent automotive testing services provider with over 170 test benches across nine locations in Germany, USA, China and Japan. ATESTEO provides a wide range of drivetrain testing services, including noise, vibration and harshness (NVH) measurements and environmental simulation, as well as tests of an entire vehicle on a dynamometer or on the road.

As well as adaptability and ease of set up, ATESTEO was also looking for a system that offered high accuracy and reliability that could operate in the harsh environments that automotive test cells have to endure.

This is because the measurement results which ATESTEO reports to car and automotive systems manufacturers steer the progress of development of the drivetrains which will be embedded in the next generation of faster, more efficient, and more dynamically effective vehicles. The accuracy, stability and traceability of these measurements are of critical importance and that means ATESTEO makes exhaustive and detailed evaluations of test instruments before deploying them in its test benches.

Modular Power Analysis

To meet its requirements, ATESTEO chose the Yokogawa WT1800E, a modular power analyser, which offers up to six input channels as well as a wide range of display and analysis features and PC connectivity.

The WT1800E meets ATESTEO’s needs with a guaranteed power accuracy of 0.05% of reading plus 0.05% of range. It is capable of harmonics analysis up to the 500th order of a 50/60 Hz fundamental frequency. The instrument also offers high stability, ensuring that precision measurements can be made reliably with the WT1800E today as well as over the long term.

ATESTEO’s engineers can use the WT1800E to make simultaneous measurements on up to six inputs at a rate of 2 MS/s; all current and voltage measurement inputs are synchronised. A mechanical channel can acquire either analogue or pulsed signals.

The instrument has a high-resolution 8.4” XGA display, which allows split-screen viewing of up to six waveforms. This makes it ideal for efficiency tests of inverter driven motors, renewable energy technologies and traction applications. The unit can display measurements in vector format or trending in time.

The built-in motor evaluation capability is ideal for ATESTEO’s testing regime as it means that it can measure more than just electrical parameters: measurement of rotation speed and direction, torque, mechanical power, synchronous speed, slip, electrical angle, motor efficiency and total system efficiency can be derived from the analogue or pulse outputs of rotation and torque sensors.

Data Capture

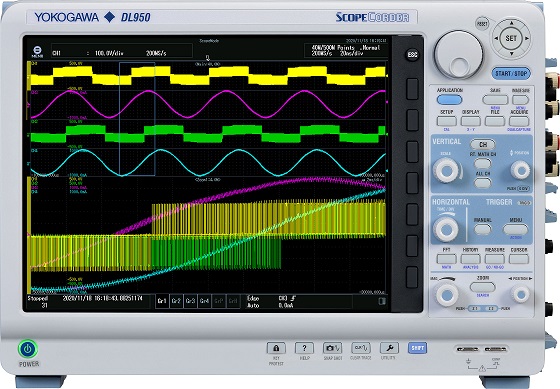

ATESTEO also opted for the Yokogawa DL950 ScopeCorder, which captures and analyses a wide variety of electrical and physical sensor signals and serial buses. It combines high sampling rates for a detailed view with long recording times to monitor trends over time. The DL950 measures signals at high resolution and secures data in the harshest environments with superior noise immunity and isolation technology.

The eight available slots on the DL950 ScopeCorder can be equipped with a selection of over 20 types of input modules to combine measurements of electrical signals, mechanical performance parameters and decoded vehicle serial bus signals. A menu simplifies the pre-measurement set-up of various applications and a large touchscreen provides for ease of use and visibility.

For both the WT1800E and the DL950, ATESTEO follows a regular 12-month calibration cycle at Yokogawa’s ISO/IEC17025 accredited (RvA K164) European Standards Laboratory in Amersfoort, The Netherlands. This enables ATESTEO to maintain full traceability of its measurements and validates the results which it supplies to its customers.

According to Andreas Olf, Branch Manager at ATESTEO’s Kassel facility, underpinning the service that the company offers is the confidence that the measurement values that it supplies to its customers for efficiency, power output, NVH and the rest are true and accurate.

“That is why we chose to continue to use Yokogawa products for power analysis. Over many years of operation, we have been able to see the results from the Yokogawa equipment are stable, accurate and reliable, and so we have no hesitation in continuing to rely on the WT1800E and DL950,” he says.

Enabling Innovation

The move to electrify the drivetrain of vehicles has prompted the automotive industry to embark on a huge innovation effort. From traction systems to transmissions to energy storage, car manufacturers are responding to the demand from road users for vehicles which allay range anxiety and which provide superior dynamic performance.

ATESTEO’s test benches provide manufacturers with critical data points to enable them to experiment with new design approaches, validate their success and implement them with confidence in production units to achieve the aims associated with new age motoring. And, according to Yokogawa, the equipment on which ATESTEO relies provides the ideal platform for the production of accurate, reliable and traceable power measurements.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020