Nissan is taking a new approach to electrified powertrain development with the sharing and modularisation of EV and e-POWER core components

The car company calls this approach to powertrain development the “X-in-1”, in which core EV and e-POWER powertrain components will be shared and modularised, resulting in a 30% reduction, compared to 2019, in development and manufacturing costs by 2026.

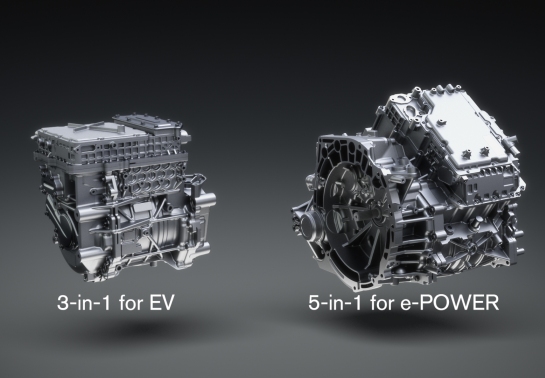

Through the X-in-1 approach, Nissan aims to increase the competitiveness of its EV and e-POWER vehicles. The modularisation involves the motor, inverter and reducer as a 3-in-1 approach with the generator and increaser added to the mix for the 5-in-1 approach, which is planned for use in e-POWER vehicles.

The X-in-1 approach, which covers 3-in-1, 5-in-1, and other possible future variants, has been developed to enable core powertrain components to be produced on the same production line.

The benefits of the approach include an approximate 30% cost reduction as well as size and weight reduction of the powertrain to improve vehicle driving performance with lower levels of noise and vibration.

According to Senior Vice President Toshihiro Hirai, who leads the powertrain & EV engineering powertrain development team at Nissan, the company has drawn on over a decade of experience in the development and production of electrified technologies.

“Through our innovations in electrified powertrain development, we’ll continue to create new value for customers and deliver 100% electric motor-driven vehicles as widely as possible,” he says.

Under its long-term vision, Nissan Ambition 2030, the company aims to bolster its lineup with 27 new electrified models, including 19 EVs, by fiscal year 2030. Nissan aims to bring the unique value of its electrified vehicles to the broadest range of customers by introducing the most suitable models to each market at the appropriate time.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020