XK10 Laser alignment system from Renishaw assists machine tool builders and other engineers with enhanced parallelism measurement accuracy

Precision measurement specialist Renishaw is releasing a new version of software for its XK10 alignment laser system. The new system enables point-to-point parallelism measurements to be performed and this new function will allow users to make precise adjustments to machine parallelism to a level that has previously been impossible using traditional measurement techniques.

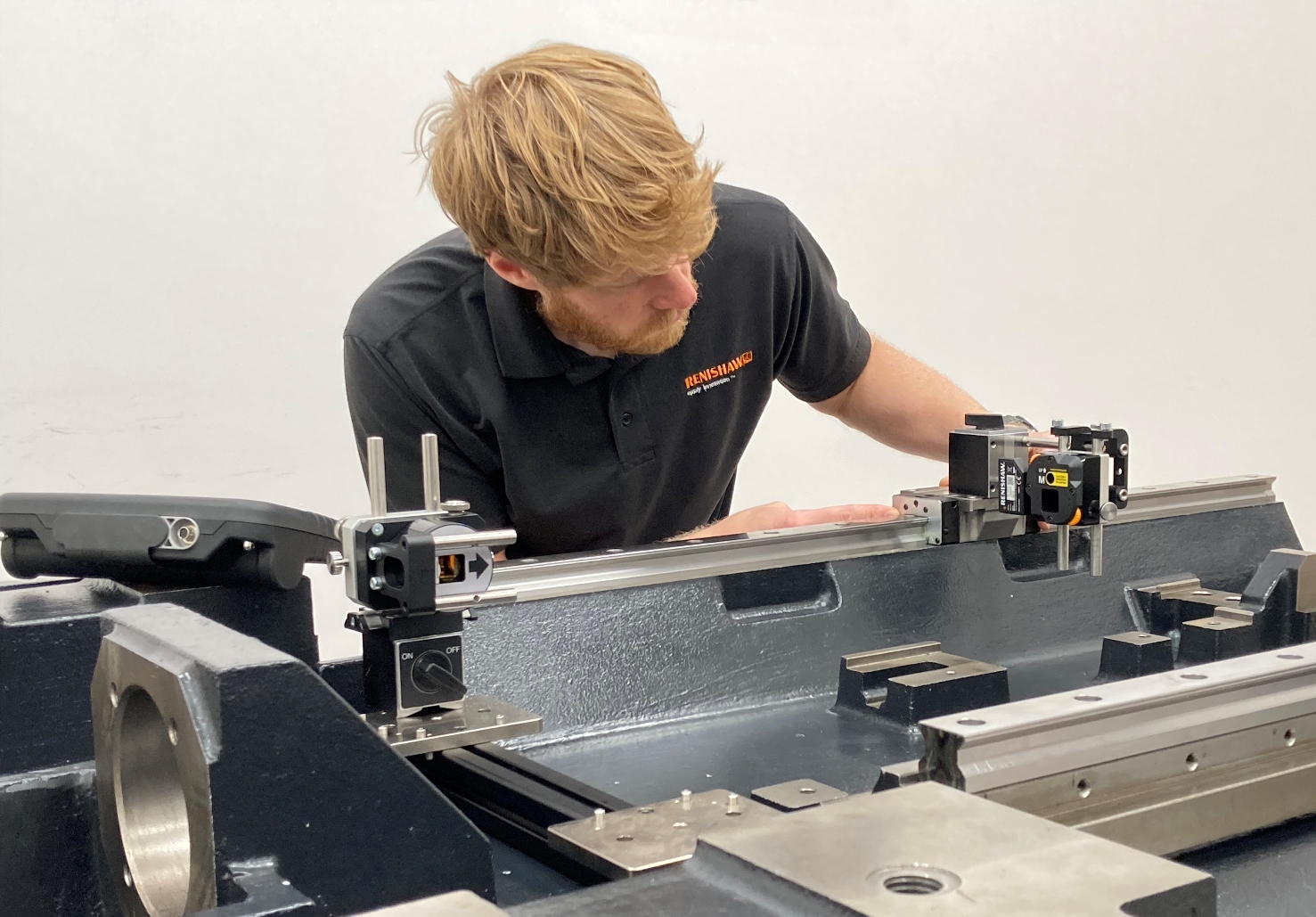

The XK10 alignment laser system provides a fast, precise and efficient measurement tool for straightness, squareness, rotational parallelism, rail parallelism, flatness and level, as well as assessing spindle direction and coaxiality of rotary machines. It is a powerful tool for diagnosing the source of errors following a rebuild or as part of regular maintenance.

Lasers replace dial gauges

The traditional method for parallelism measurement has previously been achieved by using a bridge plate and master rail, in combination with a dial gauge and level meter. This method is time-consuming and is prone to error as the measurements are recorded manually. The XK10 uses laser measurements to capture two points on each rail, allowing the angle between the two rails to be determined and recorded digitally.

According to Andy Deacon, Calibration Product Manager at Renishaw, the latest release of software enables the XK10 to take measurements at multiple points along each rail. The benefit of an increased number of measurement points is that the straightness of each rail is also measured at the same time. Parallelism between the rails can then be determined by looking at the difference in straightness at each point, giving a more accurate picture than a measurement of the overall angle between rails.

“The XK10 is supplied with fixturing components to reduce set up time and can be used with the optional parallelism optic designed specifically for this application. Making measurements where no rails are present is significantly improved using the included magnetic reference mount to easily slide the detector along the edge of a casting,” he says.

Renishaw’s calibration products, including the XL-80 laser interferometer, QC20-W ballbar and XM-60 multi-axis calibrator, are essential tools to gain a greater understanding of a machine’s capability. Regular maintenance checks of the condition of a machine, with powerful diagnosis of the source of any errors, minimises reactive maintenance effort and focus on valuable preventative work. The CARTO software suite provides data capture, analysis and compensation applications, simplifying the process for monitoring and improving position performance.