GelSight Mobile 2.4 enables new applications such as shot peening and corrosion inspection while improving overall system performance

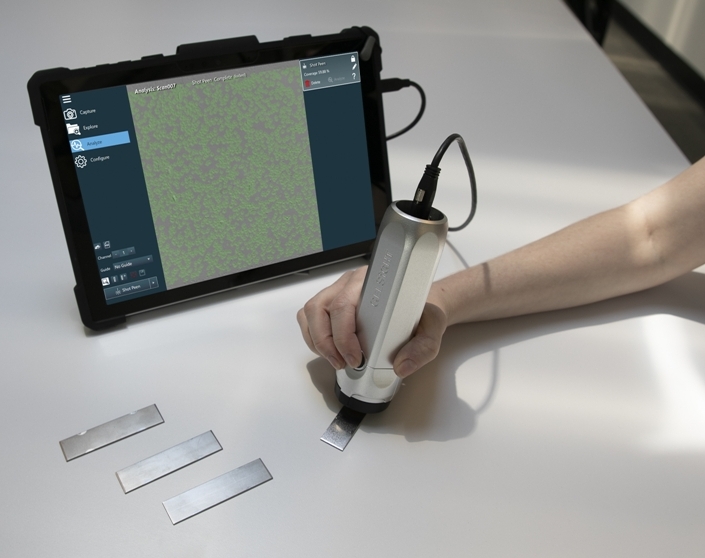

The GelSight Mobile 2.4 software update has been released for handheld mobile devices providing new features such as shot peen measurement and enhanced pit detection, as well as additional applications in quality inspection, production line metrology and maintenance.

It provides new surface analysis capabilities and improved functionality that will streamline inspection workflows. Two new features include shot peen measurement and pit detection.

Shot Peen Measurement – Evaluates the depth and coverage of shot peening to determine whether parts have been sufficiently treated to achieve the desired level of strength.

Enhanced Pit Detection – Based on input from customers using pit detection for corrosion inspection, users can now set minimum and maximum pit depths and diameters enhancing the capabilities of GelSight’s pit detection algorithm.

The technology enables digital tactile sensing with the sensitivity and resolution of human touch. Data captured by GelSight’s elastomeric tactile sensing platform uses proprietary software and algorithms to provide detailed, accurate surface characterisation that can generate significant gains in productivity both on the production floor and in the field while also reducing the costs associated with manual or tool-based visual inspection.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020