Mercedes is using its new electrified platforms to step up a gear on the development of active and passive safety technology

After developing the Electronic Stability Program (ESP) over 20 years ago, Mercedes-Benz is continuing to use this life-saving technology throughout its range whilst also developing and adapting it to assist in driver comfort and even regenerative braking performance in electric vehicles.

ESP Development

Generally, ESP stabilises the vehicle through targeted braking intervention on individual wheels. Now, these systems work in tandem with more than 100 vehicle functions to actively improve safety, efficiency and comfort in many driving situations, ranging from the integrated brakes controller and active rear axle steering to off-road functions, recuperation for electric drives, hill start assist and trailer stabilisation to the support of automated driving and numerous assistance systems.

Development milestones along the way include the regenerative braking system for hybrid and electric vehicles, which Mercedes-Benz introduced back in 2010. When braking, the electric motor switches to generator mode. The wheels transfer the kinetic energy to the generator via the drive train. The generator rotates, converting part of the kinetic energy into electrical energy. The braking torque that the electric motor generates when producing electrical energy slows down the vehicle. If more braking power is needed, additional deceleration is provided by the wheel brakes. The distribution between the generator and the braking system as well as vehicle stability, even in phases of high recuperation, is always managed by the brake control system.

ESP continues to form a crucial part of the backbone of Mercedes’ plan to achieve accident-free driving by 2050. The plan includes accident prevention, of which ESP and other assistance systems play a role, accident mitigation through passive safety technology and recovery, whereby the crashed vehicle doesn’t present further hazards.

Protection from high voltage

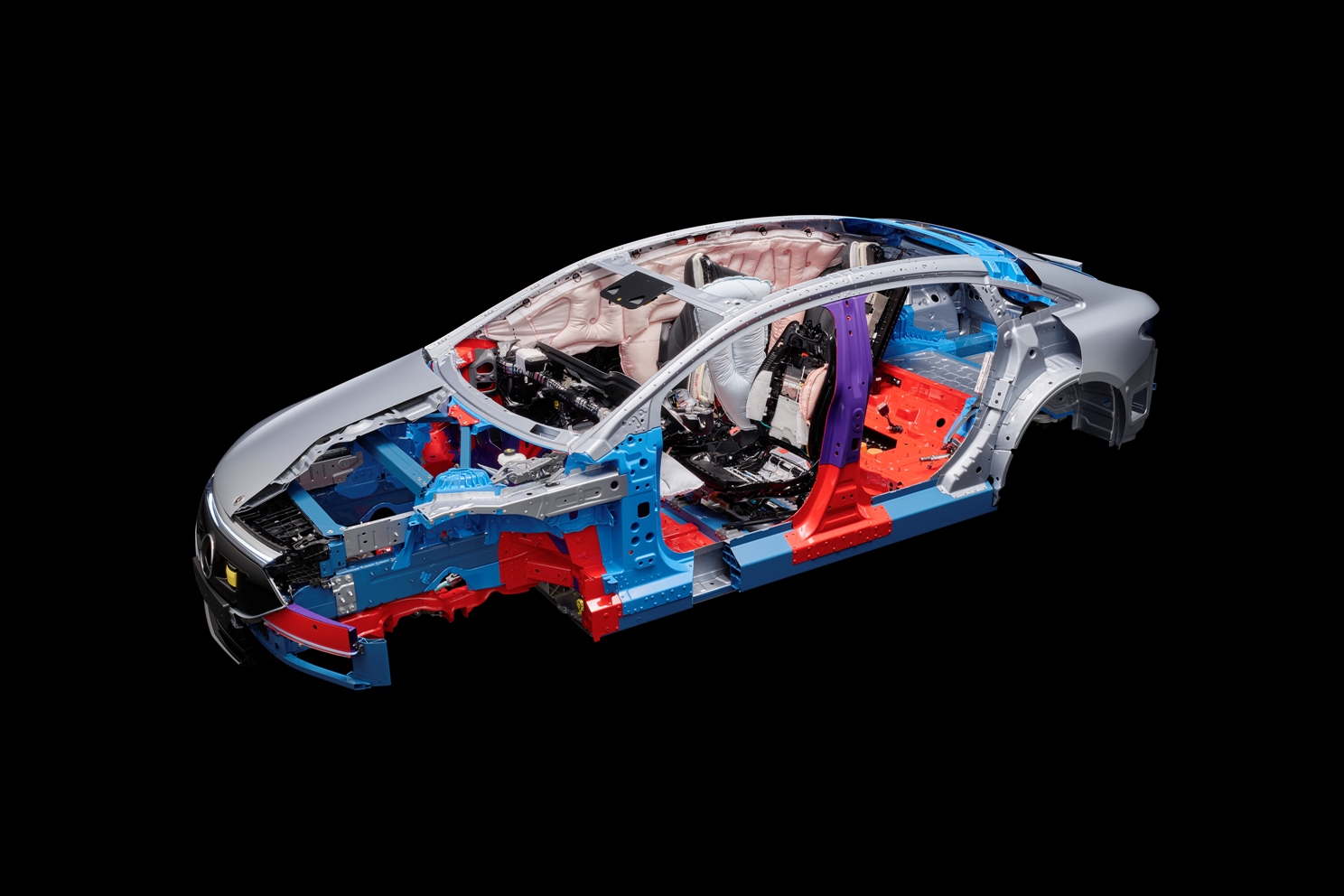

To prevent the risk of electric shock and high-energy short circuits, Mercedes has developed a multi-stage high-voltage (HV) safety concept that comprises seven essential elements. In addition to the battery, HV components comprise all components with a voltage in excess of 60 volts. If a vehicle’s sensors detect a dangerous collision, the pyrofuse safety system automatically powers down the HV system.

This protection concept provides a high level of safety whilst driving and charging as well as during and after a crash. The battery housing and the vehicle structure are matched up to ensure that all internal Mercedes‑Benz safety standard and legal requirements are met. The designers have also ensured that all HV elements are, as far as possible, placed in crash-protected areas of the vehicle.

Rear Seat Passenger Protection

In recent years, Mercedes-Benz was been able to further increase the safety of back-seat passengers. Such improvements include belt tensioners for the rear seats, side airbags and window bags, which were introduced in the S-Class in 2020. The first frontal airbag for back-seat passengers increases safety for adult passengers while also taking into account concerns about child safety.

The Belt Bag, which increases the area of the seat belt and can thus reduce impacts on the upper body, also contributes to greater safety in the rear. There is also the seat cushion airbag, which is designed to prevent passengers from slipping below the lower belt, even if the passenger has laid their seat back.

Further innovation ahead

To reach its accident-free goal by 2050, there’s still much to be done with a similar amount of time remaining as that which has passed since ESP was introduced. According to Paul Dick, Head of Vehicle Safety at Mercedes-Benz Group AG, autonomy will be a key factor in achieving it.

“We are pursuing our vision of accident-free driving and are continuing to work toward this goal at full speed. Highly automated and autonomous driving will be a decisive contributor to its success,” he says.

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020