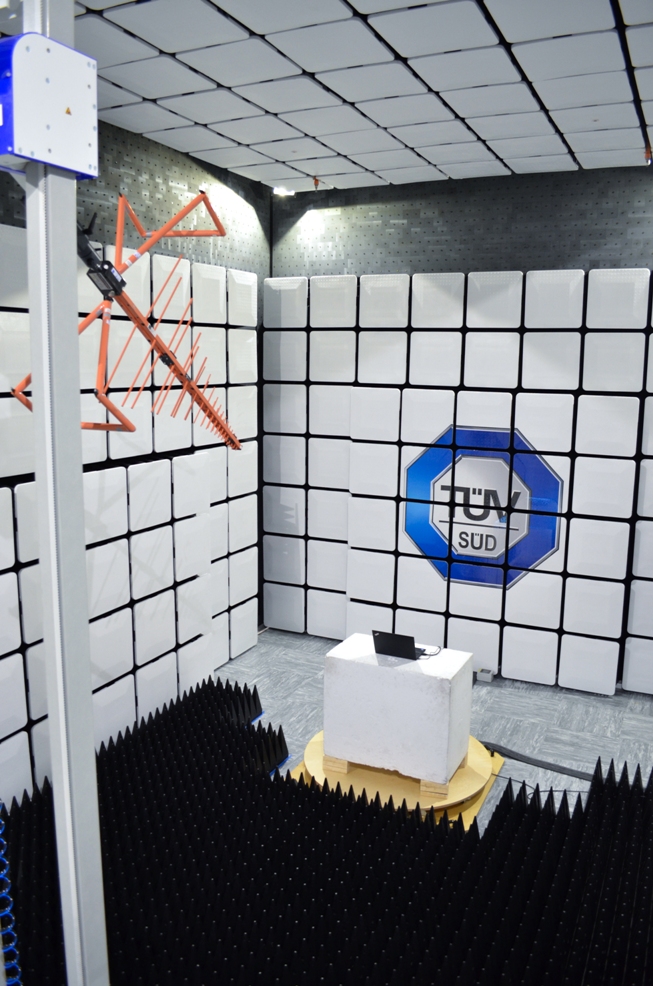

Fully automated EMC and RF testing facility increases test capacity at the company’s Hampshire based test house.

Based at TÜV SÜD’s Hampshire headquarters, the new facility’s three semi-anechoic EMC chambers will be in addition to five existing ones – significantly increasing test capacity. This will help manufacturers achieve a shorter time to market for products which integrate RF modules, including technologies such as Bluetooth, WiFi and the new 6E frequency bands. As the new chambers will also offer testing to worldwide compliance specifications, this will support growing demand from manufacturers to access multiple global markets simultaneously.

The three new EMC test chambers will be integrated with TÜV SÜD’s bespoke radiated emissions test software. This will create a fully automated system that will minimise disturbance of the device under test, so that measurements have a high level of repeatability and accuracy. The 24-hour service will also mean that tests can be completed more quickly, ensuring that manufacturers can fulfil product launch timescales.

Mary Grigsby, Head Product Service at TÜV SÜD UK, said: “Manufacturers are always under pressure to minimise market delays, and issues such as BREXIT and COVID-19, have further intensified this. However, as a growing number of products are being developed to take advantage of wireless connectivity, this increased complexity necessitates more testing. TÜV SÜD’s investment in a highly advanced automated EMC test facility means that we can customise our service to provide the most efficient route to market, to ensure that testing is completed on time and lead times are minimised.”

- UK manufacturing steps up to COVID-19 crisis - April 2, 2020

- Clustering Innovation - March 12, 2020

- A Global Monitor - March 6, 2020